Unipower GT Blog from Cornwall - Part 7

- Admin

- Apr 27, 2022

- 2 min read

My body has been neglected for a while (no comments on that please!) and will continue to be for a little longer….

Meanwhile, finishing touches to the engine with its correct BMC green paint (heat resistant too, I’m assured) were made to the engine/gearbox and some ancillaries, so it all looks ex-factory. Also fitted was the correct ‘Morris’ rocker cover decal, new oil filler cap, correct rocker cover fixings, correct yellow paint on the water pump pulley, secured with genuine ex-factory UNF ¼” set screws. Similarly, the clutch cover, slave cylinder and coil mounting plate are secured with ex-factory UNC screws. Doesn’t get more original than that! More on the factory fixings later….

Along with a new dynamo bracket, a new pivot bolt, clutch stop and locknut, original new heater valve along with a new thermostat housing, with Gerry Hulford reminding me that it’s fitted with the outlet pipe pointing to the rear of the car, not forward as in conventional installations. A little fettling needed there.

Drivetrain items all were refurbed and high tensile cap-headed bolts fitted to the drive flanges, new gaiters inboard and outboard together with original steel securing clips. All painted in correct black.

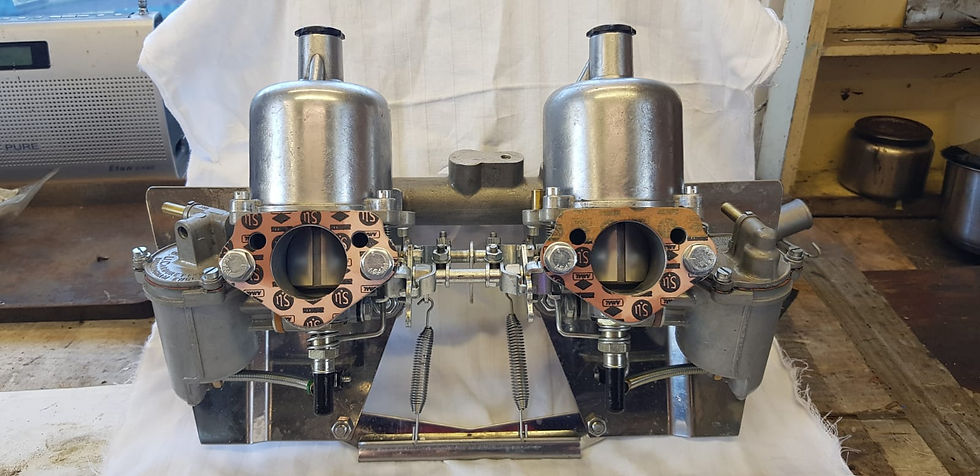

The twin 1-1/4” SU carbs are overhauled and ready to fit but the exhaust manifold is to be a modified LCB together with a new silencer which will be fitted a bit further down the road when the engine is in and the car rolling! (When will this be? Ed.)

That really is the powertrain done and now it’s back to my body….

Radiator to be checked, then installed along with new hoses connecting to the new stainless tubes connecting front to rear. NB the factory did not use stainless here, but in the interests of longevity and practicality I’ve used stainless, painted black.

But, before the radiator got a look-in, something had been looking at me across the workbench for ages…. some electrical stuff…. the new voltage regulator (don’t forget we’re still going with a dynamo here, not bothering with a dynalternator) and the nicely cleaned up fuse box. All were then mounted with new 2 BA screws (factory nuts too) to the original, now highly polished alloy plate, which will be secured to the rear bulkhead. Beautiful!

Rad stuff for those who can’t wait will follow in part 8 of the ‘Blog from Cornwall’

Ed (Gerry): Thanks to Guy once again for providing such a great update on the major rebuild he is undertaking on his car (UWF1005) to restore it back to factory built specification/condition. This will make it the most 'factory correct' car residing in the UK, and with the exception of one of the very last cars built, which I sold to an owner in Japan over 30-years ago now (previously owned by Guy's father in fact), one of the only factory correct cars in the World in running order. We all look forward to the next stages of the restoration and especially the fettling of the new body in preparation for the unique paint scheme that will replicate what his father specified back in 1969, making it the only two-tone coloured car produced by the factory.

Great job that you are doing Guy - an inspiration!

Guy, by the time you have finished the build of your Unipower GT it will be a beautiful example of the marque, keep up the good work.