UNIPOWER GT TM

Owners Club & Register

The worldwide Owners Club founded in 1972

"The Mini-Miura"

The Club for Owners and Enthusiasts of the marque

NEC Classic Motor Show

7th - 9th November 2025

The Club once again participated in the annual Classic Motor Show with our stand in Hall 3 where we celebrated the Unipower GT's 60th Anniversary with three of the best examples of the marque. A little over 72,500 visitors crowded the NEC over the three days and our stand certainly had its fair share.

Take a look at our Show reports and a video interview reported in the Club Blog pages on this site.

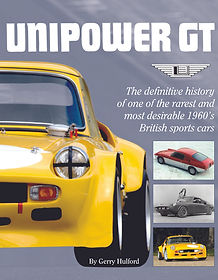

The first book to be published on the history of the Unipower GT

Click the BUY NOW button below or visit the Club's Shop to purchase a copy. Please note that ONLY copies purchased through this website will be signed by the Author if requested.

Latest Club Blog Posts

-

Featured Cars

Unipower GT 1966

Chassis #1266.7

This road spec chassis was built towards the end of 1966, becoming the factory demonstration car that would appear in all the magazine articles and road-tests of that period.

Fitted with a 998cc Cooper engine, as UPD had thought that this would be the most popular choice of customers, it was the very first production car fitted with sliding door windows. The earlier cars being retro fitted with new doors and sliding windows due to issues with the original wind-up windows not sealing well enough.

Fitted with all the factory options available at that time it was subject to additional options as time went on. Remaining with the factory until its closure in late 1969, the car was sold to the factory's Storeman who then sold it on to the then Unipower agent, Monty & Ward Motors in Kent in 1971. It was then bought by Gerry Hulford as his first Unipower GT and was to go on to complete a huge mileage over the next 12-years and being fitted with a sunroof and repainted Aquatic Jade, one of the factory colours.

Club Website recent updates

-

Latest Blog on LTM 80G crash repairs

-

New Videos from Unipower Team Denmark loaded

Unipower GT Restorations - Latest Updates

The last of Unipower GT's being rebuilt is well into its final stages of its total restoration. To see how this car is progressing and reports on other earlier rebuilds click HERE...

Two Unipower GT are currently for sale in the UK. More details on these cars click HERE....

Fabrication of various parts like gearchanges are just some of the many parts available to owners as well as many other hard to find or obsolete parts including original body panels. See HERE....

The Club on Facebook and Instagram

For some time now the Club has had a presence on Facebook and Instagram. Click on the Icons to go to our pages

Interested in buying a Unipower GT ?

If you are interested in buying a Unipower GT, then register to be notified of cars when they come up for sale HERE....

Unipower GT - Registered Trade Mark

The Club is pleased to announce that the name 'Unipower GT' has been legally registered as a Trade Mark belonging to the Club's founder

.jpg)